Description

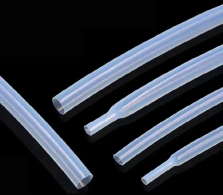

Material: fluorinated ethylene propylene (FEP)

Shrink ratio: 1.3:1

Features:

◆ RoHS, REACH, FDA compliance, available for medical field

◆ High temperature resistance, high transparency

◆ Flame retardant, semi-rigid

◆ Excellent mechanical, solvent, corrosion resistance

◆ Working temperature: -50℃~200℃

◆ Minimum shrink temperature: 100℃

Application:

With high transparency and high temperature resistance, heat shrinkable tubing is widely used in industries like electronics, optics, medical, automotive, telecom, aerospace etc.

Specifications:

| Items | Test Methods | Specifications |

| Specific gravity | ASTM D792 | 2.15g/cm3 |

| Water absorption | ASTM D570 | <0.01% |

| Oxygen index | ASTM D2863 | ≥95% |

| Tensile strength | ASTM D638 | 18MPa~34MPa |

| Elongation at break | ASTM D638 | 245%~400% |

| Melting point | – | 260℃~270℃ |

| Flammability | UL224 | VW-1 |

| Volume resistance | ASTM D257 | ≥1.0×1018Ω.cm |

| Dielectric strength | ASTM D2671 | AC 2500V, 60s, no breakdown |

Size:

| Size | As Supplied(mm) | After Recovery (mm) | ||

| Inside Diameter | Wall-thickness | Inside Diameter | Wall-thickness | |

| Ф2.0 | 2.0±0.2 | 0.20±0.05 | ≤1.6 | 0.25±0.05 |

| Ф3.0 | 3.0±0.3 | 0.20±0.05 | ≤2.4 | 0.25±0.05 |

| Ф4.0 | 4.0±0.3 | 0.20±0.05 | ≤3.1 | 0.25±0.05 |

| Ф5.0 | 5.0±0.3 | 0.20±0.05 | ≤3.9 | 0.25±0.05 |

| Ф6.0 | 6.0±0.3 | 0.20±0.05 | ≤4.7 | 0.25±0.05 |

| Ф7.0 | 7.0±0.3 | 0.20±0.05 | ≤5.4 | 0.25±0.05 |

| Ф8.0 | 8.0±0.3 | 0.20±0.05 | ≤6.2 | 0.25±0.05 |

| Ф9.0 | 9.0±0.3 | 0.20±0.05 | ≤6.9 | 0.25±0.05 |

| Ф10.0 | 10.0±0.4 | 0.20±0.05 | ≤7.8 | 0.25±0.05 |

| Ф11.0 | 11.0±0.4 | 0.20±0.05 | ≤8.5 | 0.25±0.05 |

Other sizes and colors are available upon special order.