Description

Material: PA66 or PA6

Features:

◆ UL approved material, fire resistance level UL94-V2

◆ Good acid & corrosion resistance, and insulation performance

◆ Good ageing resistance, and strong bearing force.

◆ Operating temperature: 0℃~85℃

◆ Color: white (natural), black, and other colors.

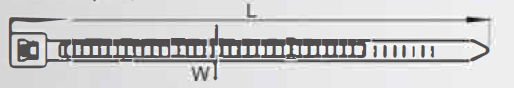

Size:

| Item No. | Length (L) | Width (W) (mm) | Bundle Range (E) (mm) | Min. Loop Tensile Stength | ||

| inch | mm | LBS | KGS | |||

| TH-3×60 | 2 3/8 | 60 | 2.5 | 2-11 | 18 | 8 |

| TH-3×80 | 3 3/16 | 80 | 2.5 | 2-16 | 18 | 8 |

| TH-3×100 | 4 | 100 | 2.5 | 2-22 | 18 | 8 |

| TH-3×120 | 4 3/4 | 120 | 2.5 | 2-30 | 18 | 8 |

| TH-3×140 | 5 1/2 | 140 | 2.5 | 2-33 | 18 | 8 |

| TH-3×150 | 6 | 150 | 2.5 | 2-35 | 18 | 8 |

| TH-3×160 | 6 1/4 | 160 | 2.5 | 2-40 | 18 | 8 |

| TH-3×200 | 8 | 200 | 2.5 | 3-50 | 18 | 8 |

| TH-3×250 | 10 | 250 | 2.5 | 3-65 | 18 | 8 |

| TH-4×100 | 4 | 100 | 3.6 | 3-22 | 40 | 18 |

| TH-4×120 | 4 3/4 | 120 | 3.6 | 3-30 | 40 | 18 |

| TH-4×150 | 6 | 150 | 3.6 | 3-35 | 40 | 18 |

| TH-4×180 | 7 | 180 | 3.6 | 3-42 | 40 | 18 |

| TH-4×200 | 8 | 200 | 3.6 | 3-50 | 40 | 18 |

| TH-4×250 | 10 | 250 | 3.6 | 3-65 | 40 | 18 |

| TH-4×300 | 11 5/8 | 300 | 3.6 | 3-80 | 40 | 18 |

| TH-4×350 | 13 3/4 | 350 | 3.6 | 3-90 | 40 | 18 |

| TH-4×370 | 14 1/2 | 370 | 3.6 | 3-102 | 40 | 18 |

| TH-4×400 | 15 3/4 | 400 | 3.6 | 3-105 | 40 | 18 |

| TH-5×100 | 4 | 100 | 4.6 | 2-22 | 50 | 22 |

| TH-5×120 | 4 3/4 | 120 | 4.8 | 3-30 | 50 | 22 |

| TH-5×150 | 6 | 150 | 4.8 | 3-35 | 50 | 22 |

| TH-5×160 | 6 1/4 | 160 | 4.8 | 3-50 | 50 | 22 |

| TH-5×200 | 8 | 200 | 4.8 | 3-50 | 50 | 22 |

| TH-5×250 | 10 | 250 | 4.8 | 3-65 | 50 | 22 |

| TH-5×300 | 11 5/8 | 300 | 4.8 | 3-82 | 50 | 22 |

| TH-5×350 | 13 3/4 | 350 | 4.8 | 3-90 | 50 | 22 |

| TH-5×370 | 14 1/4 | 370 | 4.8 | 3-102 | 50 | 22 |

| TH-5×400 | 15 3/4 | 400 | 4.8 | 3-105 | 50 | 22 |

| TH-5×430 | 17 | 430 | 4.8 | 3-110 | 50 | 22 |

| TH-5×450 | 17 3/4 | 450 | 4.8 | 3-130 | 50 | 22 |

| TH-5×500 | 19 11/16 | 500 | 4.8 | 3-150 | 50 | 22 |

| TH-5.5×370 | 14 1/4 | 370 | 5.5 | 3-98 | 85 | 30 |

| TH-5.5×650 | 25 9/16 | 650 | 5.5 | 8-185 | 85 | 30 |

| TH-6×350 | 13 3/4 | 350 | 6.0 | 4-90 | 85 | 38 |

| TH-6×400 | 15 3/4 | 400 | 6.0 | 4-105 | 85 | 38 |

| TH-6×450 | 17 3/4 | 450 | 6.0 | 4-110 | 85 | 38 |

| TH-6.5×300 | 11 5/8 | 300 | 6.5 | 4-90 | 85 | 38 |

| TH-6.5×370 | 14 1/4 | 370 | 6.5 | 3-98 | 85 | 38 |

| TH-7.0×400 | 16 | 400 | 7.0 | 4-105 | 120 | 55 |

| TH-7.0×450 | 18 | 450 | 7.0 | 4-110 | 120 | 55 |

| TH-8×150 | 6 | 150 | 7.6 | 3-33 | 120 | 55 |

| TH-8×200 | 8 | 200 | 7.6 | 3-50 | 120 | 55 |

| TH-8×250 | 10 | 250 | 7.6 | 4-63 | 120 | 55 |

| TH-8×300 | 11 5/8 | 300 | 7.6 | 4-82 | 120 | 55 |

| TH-8×350 | 13 3/4 | 350 | 7.6 | 4-90 | 120 | 55 |

| TH-8×370 | 14 1/4 | 370 | 7.6 | 4-98 | 120 | 55 |

| TH-8×400 | 15 3/4 | 400 | 7.6 | 4-105 | 120 | 55 |

| TH-8×450 | 17 3/4 | 450 | 7.6 | 4-118 | 120 | 55 |

| TH-8×500 | 19 11/16 | 500 | 7.6 | 4-150 | 120 | 55 |

| TH-8×550 | 21 11/16 | 550 | 7.6 | 4-160 | 120 | 55 |

| TH-9×400 | 16 | 400 | 8.8 | 8-105 | 120 | 55 |

| TH-9×450 | 17 3/4 | 450 | 8.8 | 4-118 | 175 | 80 |

| TH-9×500 | 19 11/16 | 500 | 8.8 | 4-150 | 175 | 80 |

| TH-9×550 | 21 1/16 | 550 | 8.8 | 8-160 | 175 | 80 |

| TH-9×600 | 23 5/8 | 600 | 8.8 | 8-170 | 175 | 80 |

| TH-9×650 | 25 9/16 | 650 | 8.8 | 8-190 | 175 | 80 |

| TH-9×720 | 27 1/2 | 720 | 8.8 | 10-205 | 175 | 80 |

| TH-9×760 | 30 5/8 | 760 | 8.8 | 8-225 | 175 | 80 |

| TH-9×800 | 31 | 800 | 8.8 | 10-230 | 175 | 80 |

| TH-9×850 | 34 | 850 | 8.8 | 10-255 | 175 | 80 |

| TH-9×920 | 36 1/4 | 920 | 8.8 | 10-265 | 175 | 80 |

| TH-9×1020 | 40 1/6 | 1020 | 8.8 | 10-295 | 175 | 80 |

| TH-9×1220 | 48 | 1220 | 8.8 | 10-340 | 175 | 80 |

| TH-12.5×500 | 19 11/16 | 500 | 12.5 | 4-150 | 250 | 114 |

| TH-12.5×550 | 21 1/16 | 550 | 12.5 | 8-160 | 250 | 114 |

| TH-12.5×650 | 59/16 | 650 | 12.5 | 8-190 | 250 | 114 |

| TH-12.5×730 | 28 3/4 | 730 | 12.5 | 8-216 | 250 | 114 |

| TH-12.5×880 | 34 16/25 | 880 | 12.5 | 8-264 | 250 | 114 |

| TH-12.5×1030 | 43 | 1030 | 12.5 | 8-312 | 250 | 114 |